Fluorosilicone Rubber, especially fluorosilicone rubber, is widely used in power systems, mainly in the following aspects:

1. Radiator hose

Radiator hose is a vital component in the power system, used to transmit coolant to maintain the normal operating temperature of the engine. Fluorosilicone rubber has become an ideal material for manufacturing radiator hoses due to its excellent heat resistance, cold resistance and aging resistance. This material can ensure stable performance in both high and low temperature environments, and is not easy to age or crack, thereby extending the service life of the radiator hose.

2. Turbocharger hose

Turbocharger hose is a key component connecting the turbocharger and the engine intake duct. Since the turbocharger generates high temperature and high pressure when working, the hose needs to withstand extreme temperature and pressure conditions. Fluorosilicone rubber has excellent high temperature resistance, high pressure resistance and chemical corrosion resistance, which can meet the working requirements of turbocharger hoses and ensure the normal operation of the turbocharger system.

3. Air delivery hose

In the power system, the air delivery hose is used to deliver air from the air filter to the engine intake duct. Fluorosilicone rubber hoses can resist the erosion of dust, water vapor and other pollutants in the air, keeping the air delivery pipeline clean and unobstructed. At the same time, its excellent flexibility and wear resistance also make the hoses not easy to be damaged during long-term use, ensuring the stability and reliability of the power system.

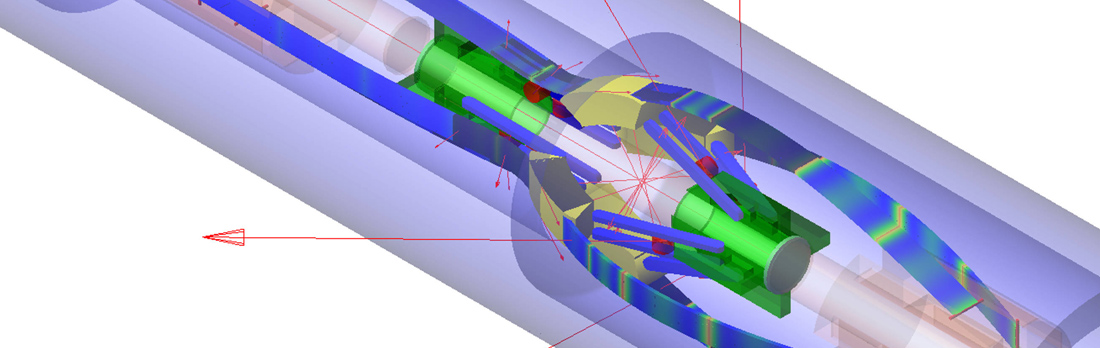

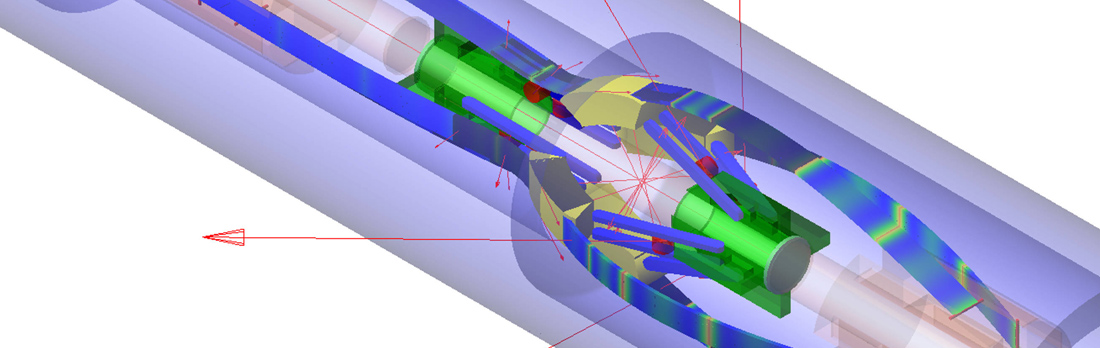

4. Other power system components

In addition to the radiator hoses, turbocharger hoses and air delivery hoses mentioned above, fluorosilicone rubber is also widely used in other components of the power system, such as gaskets, O-rings, valves, etc. These components need to withstand high temperature, high pressure and corrosive media, and the excellent performance of fluorosilicone rubber makes it an ideal choice for these components.

5. Application advantages

High temperature resistance: Fluorosilicone rubber can maintain stable performance in high temperature environments and will not fail due to temperature increases.

Chemical corrosion resistance: Fluorosilicone rubber can resist the erosion of a variety of chemicals, including acids, alkalis and organic solvents.

Aging resistance: Fluorosilicone rubber has a lower glass transition temperature, so it usually has a wider operating temperature range than fluororubber and better aging resistance.

Flexibility: Fluorosilicone rubber has excellent flexibility and can adapt to various complex shapes and size requirements.

In summary, fluorosilicone rubber has broad application prospects and advantages in power systems. With the continuous advancement of science and technology and the continuous development of power systems, the application scope of fluorosilicone rubber will be further expanded, providing a stronger guarantee for the stability and reliability of power systems.