The use of

fluorosilicone oil in steam power circulation system is mainly based on its unique chemical and physical properties. The following is a detailed analysis of the use of fluorosilicone oil in steam power circulation system:

1. Properties of fluorosilicone oil

Fluorosilicone oil is a colorless or light yellow transparent liquid, which belongs to modified silicone oil. Because it introduces trifluoropropyl on the silicon atom, it has the characteristics of corrosion resistance, solvent resistance, oil resistance, high and low temperature resistance, low surface tension and low refractive index. These characteristics make fluorosilicone oil have a wide range of application prospects in steam power circulation system.

2. Application of fluorosilicone oil in steam power circulation system

Lubricant:

Fluorosilicone oil has good lubricity under extreme pressure conditions, which can significantly reduce the friction factor of friction pairs and extend the service life of equipment.

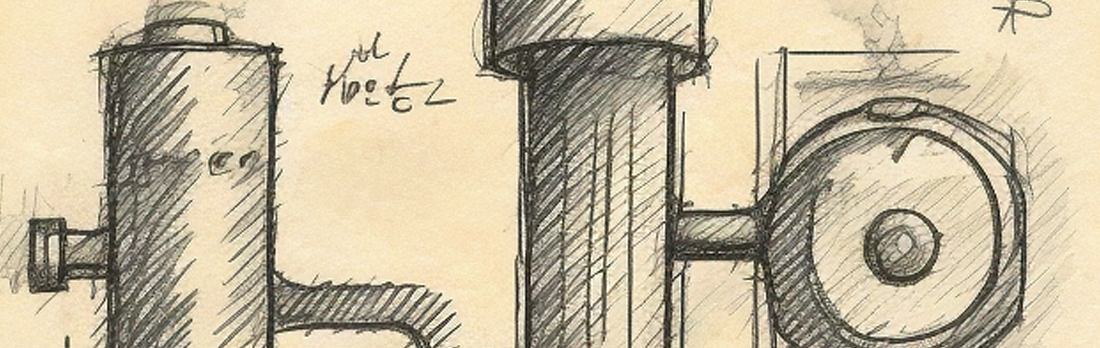

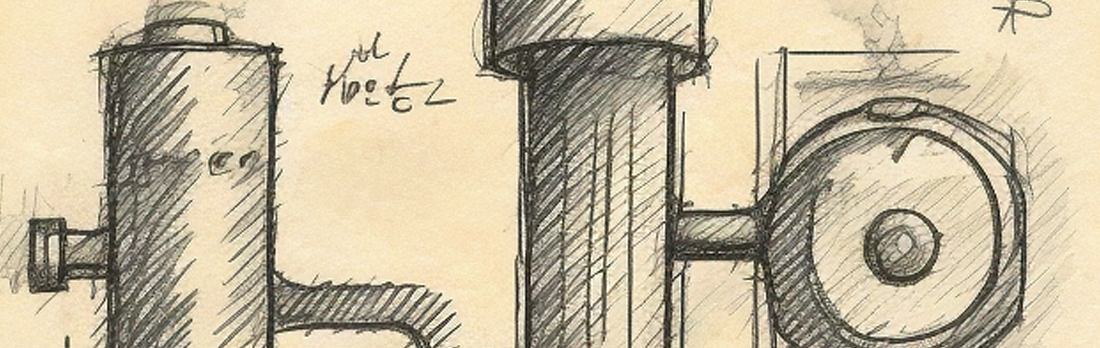

In steam power circulation system, fluorosilicone oil can be used as a lubricant for bearings and other components to reduce friction and wear between components and improve the operating efficiency of the system.

Chemical inertness:

Fluorosilicone oil is chemically inert to fuels and other chemicals, which means that it will not react chemically with these substances.

In the steam power cycle system, fluorosilicone oil can be used as a lubricant or sealant for parts in contact with fuel and other chemicals to ensure the safety and stability of the system.

High and low temperature resistance:

Fluorosilicone oil has a wide operating temperature range (-60~200℃), which enables it to cope with various temperature changes in the steam power cycle system.

In high or low temperature environments, fluorosilicone oil can still maintain its lubricity and chemical stability to ensure the normal operation of the system.

3. Advantages of fluorosilicone oil in steam power cycle system

Improve system efficiency:

As a lubricant, fluorosilicone oil can reduce friction and wear between components and reduce energy loss, thereby improving the efficiency of the steam power cycle system.

Enhance system stability:

The chemical inertness and high and low temperature resistance of fluorosilicone oil enable it to maintain stable performance in the steam power cycle system, and will not deteriorate or fail due to changes in temperature or chemical environment.

Extend equipment life:

Using fluorosilicone oil as a lubricant can reduce wear between components, thereby extending the service life of the equipment and reducing maintenance and replacement costs.

In summary, fluorosilicone oil has broad application prospects and significant advantages in steam power cycle systems. It can act as a lubricant to reduce friction and wear and improve system efficiency; at the same time, its chemical inertness and high and low temperature resistance make the system more stable and reliable; in addition, it can extend the service life of the equipment and reduce maintenance costs. Therefore, using fluorosilicone oil in steam power cycle systems is a wise choice.