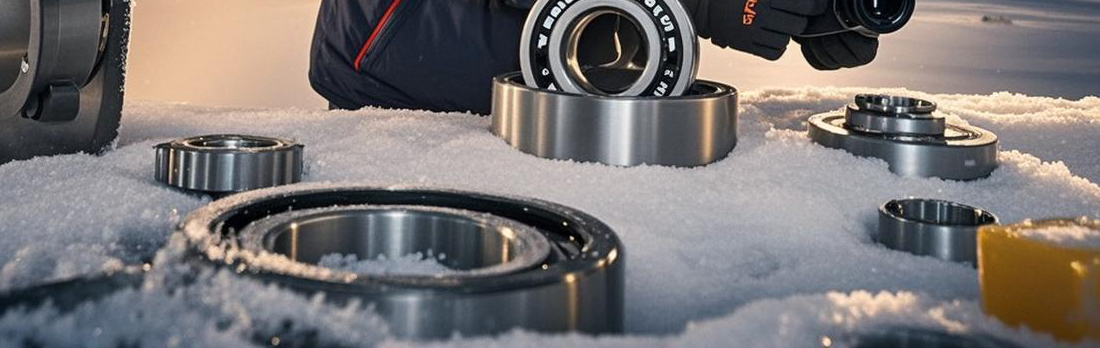

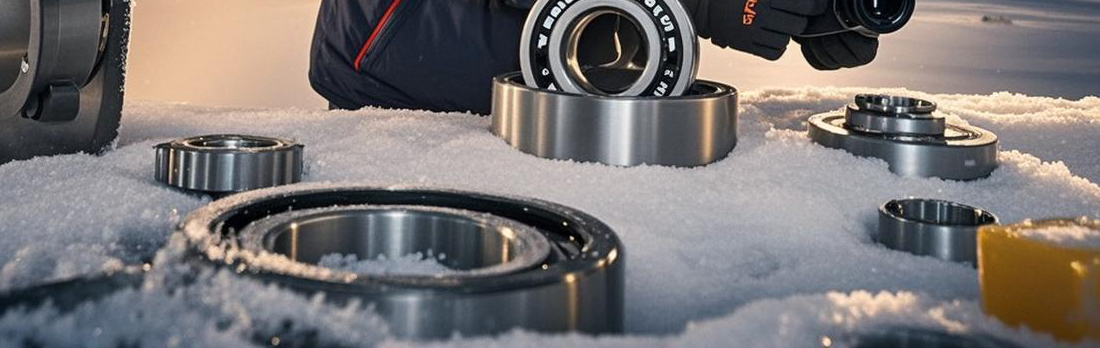

In extremely low or high temperature environments,

fluorosilicone oil shows excellent lubricating effect in bearing lubrication.

On the one hand, fluorosilicone oil has excellent oil resistance, solvent resistance and chemical stability, which makes it stable under extreme conditions. It can form a molecular assembly film with an outer chemical composition of -CF3 and high hydrophobicity and oleophobicity on the surface of the substrate through chemical adsorption, which can greatly reduce the friction coefficient of the substrate and make it have good wear resistance under low load. In addition, fluorosilicone oil also has a high viscosity-temperature coefficient and will not wax or rapidly reduce viscosity with the increase of temperature, thereby ensuring its lubrication performance in high temperature environments.

On the other hand, fluorosilicone oil can meet the lubrication requirements of vacuum equipment and low-temperature equipment bearings working in high temperature and high humidity environments. Experimental data show that fluorosilicone oil has excellent high-temperature lubrication performance, and its operating temperature range can reach -40~240℃. Therefore, in extremely low or high temperature environments, fluorosilicone oil can still maintain its lubrication performance and provide effective lubrication for bearings.

Specifically, the advantages of fluorosilicone oil in bearing lubrication include:

Significantly reduce the friction coefficient: Fluorosilicone oil can form a lubricating film on the bearing surface, thereby significantly reducing the friction coefficient, reducing bearing wear and energy consumption.

Improve wear resistance: The lubricating film of fluorosilicone oil has excellent wear resistance and can extend the service life of the bearing.

Adapt to extreme temperature environments: Fluorosilicone oil can remain stable in both high and low temperature environments, providing reliable lubrication for bearings.

In summary, fluorosilicone oil shows excellent lubrication effect in bearing lubrication in extremely low or high temperature environments, and is an important material in the field of bearing lubrication.