The application of fluorosilicone oil in vacuum pump lubricants is mainly due to its unique chemical structure and excellent physical properties. The following is a detailed analysis of the application of fluorosilicone oil in vacuum pump lubricants:

1. Characteristics of fluorosilicone oil

High and low temperature resistance: Fluorosilicone oil has very good thermal stability and can maintain its physical properties at extremely high or low temperatures, making it suitable for extreme environments. Its wide range of operating temperatures, generally between -40 and 240°C, enables it to provide effective lubrication for vacuum pumps under various harsh temperature conditions.

Chemical resistance: Fluorosilicone oil has strong corrosion resistance and solubility resistance to a variety of chemicals, including acids, alkalis, solvents, etc. This feature enables fluorosilicone oil to maintain stable lubrication performance in vacuum pumps that handle chemical reaction gases without being corroded by chemicals.

Excellent lubricity: When used as a lubricant, fluorosilicone oil has a low friction coefficient and good lubrication performance. It can form a molecular assembly film with high hydrophobicity and oleophobicity on the surface of the substrate, greatly reducing the friction coefficient of the substrate and giving it good wear resistance under low load. This property enables fluorosilicone oil to meet the lubrication needs of vacuum pumps under high load and high speed conditions.

Low surface tension: Fluorosilicone oil has a low surface tension, which makes it have good waterproof, anti-fouling and anti-sticking properties. In vacuum pumps, this property helps to reduce the adhesion between the pump oil and the pump body, improve the fluidity of the pump oil, and thus enhance the lubrication effect.

Electrical insulation: Fluorosilicone oil has excellent electrical insulation properties, which makes it widely used in electrical equipment. In vacuum pumps, this property helps to ensure that the pump oil will not deteriorate or fail due to electrical discharge.

2. Application of fluorosilicone oil in vacuum pump lubricants

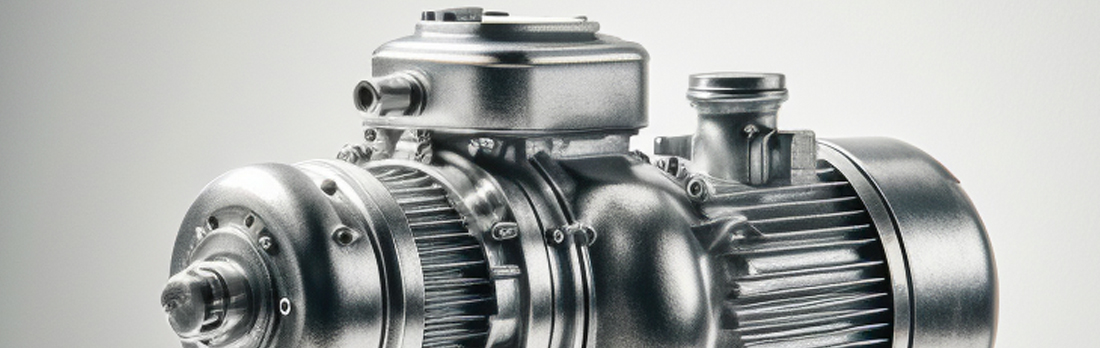

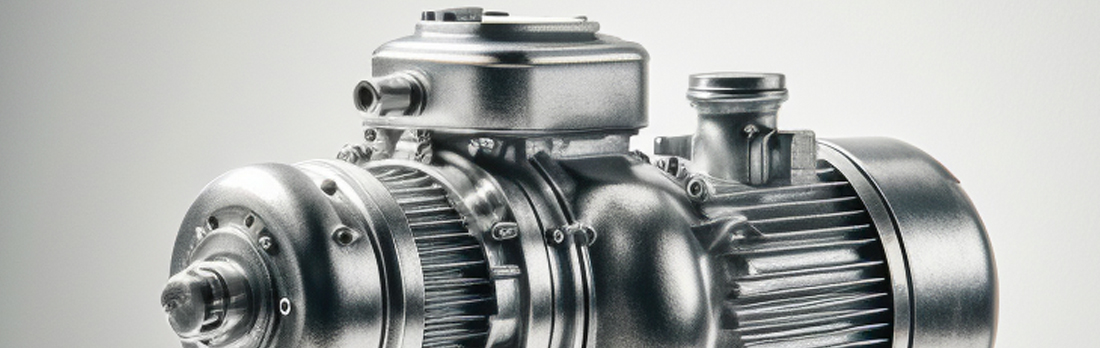

Lubricating effect: Fluorosilicone oil can penetrate between the various moving parts of the vacuum pump, such as rotors, vanes, bearings and shaft seals, to provide effective lubrication. This helps to reduce friction and wear between parts and extend the service life of the vacuum pump.

Sealing effect: Fluorosilicone oil has a certain viscosity and can form an oil film inside the vacuum pump to play a sealing role. This helps prevent the atmosphere from returning to the pump through the exhaust valve and ensures good air tightness when the exhaust valve is closed.

Cooling effect: Fluorosilicone oil can take away the heat generated inside the vacuum pump during the lubrication process and play a cooling role. This helps to maintain the normal operating temperature of the vacuum pump and prevent damage due to overheating.

Reduce the impact of harmful space: Fluorosilicone oil can fill the harmful space inside the vacuum pump and reduce the high-pressure residual gas therein. This helps to reduce the impact of harmful space on the ultimate vacuum and improve the vacuum pump's pumping efficiency.

In summary, fluorosilicone oil has a wide range of application prospects in vacuum pump lubricants due to its unique chemical structure and excellent physical properties. It can provide effective lubrication, sealing, cooling and reduce the impact of harmful space, which helps to extend the service life of the vacuum pump and improve the pumping efficiency.