Ethyl silicone lubricants play an important role in lubrication and reliability in robots and automation equipment. The following is a detailed analysis of this aspect:

1. Characteristics of ethyl silicone lubricants

Excellent lubrication performance: Ethyl silicone oil has excellent lubrication performance, which can effectively reduce friction and wear between moving parts in robots and automation equipment, thereby improving the operating efficiency and life of the equipment.

Wide operating temperature range: The operating temperature range of ethyl silicone oil is usually between -60℃ and 150℃, which enables it to maintain stable lubrication performance under various extreme temperature conditions to ensure the normal operation of the equipment.

Low volatility: Ethyl silicone oil has low volatility, which means that it is not easy to volatilize during long-term use, thereby reducing the frequency of lubricant replenishment and reducing maintenance costs.

Chemical inertness: Ethyl silicone oil is inert to metals, alloys, plastics, polymers, rubber and other materials, and will not corrode or damage these materials, ensuring the integrity of components in robots and automation equipment.

Good dielectric properties: The good dielectric properties of ethyl silicone oil make it the preferred lubricant in electrical machinery, which can ensure lubrication without affecting the electrical performance of the equipment.

2. Application of ethyl silicone oil lubricants in robots and automation equipment

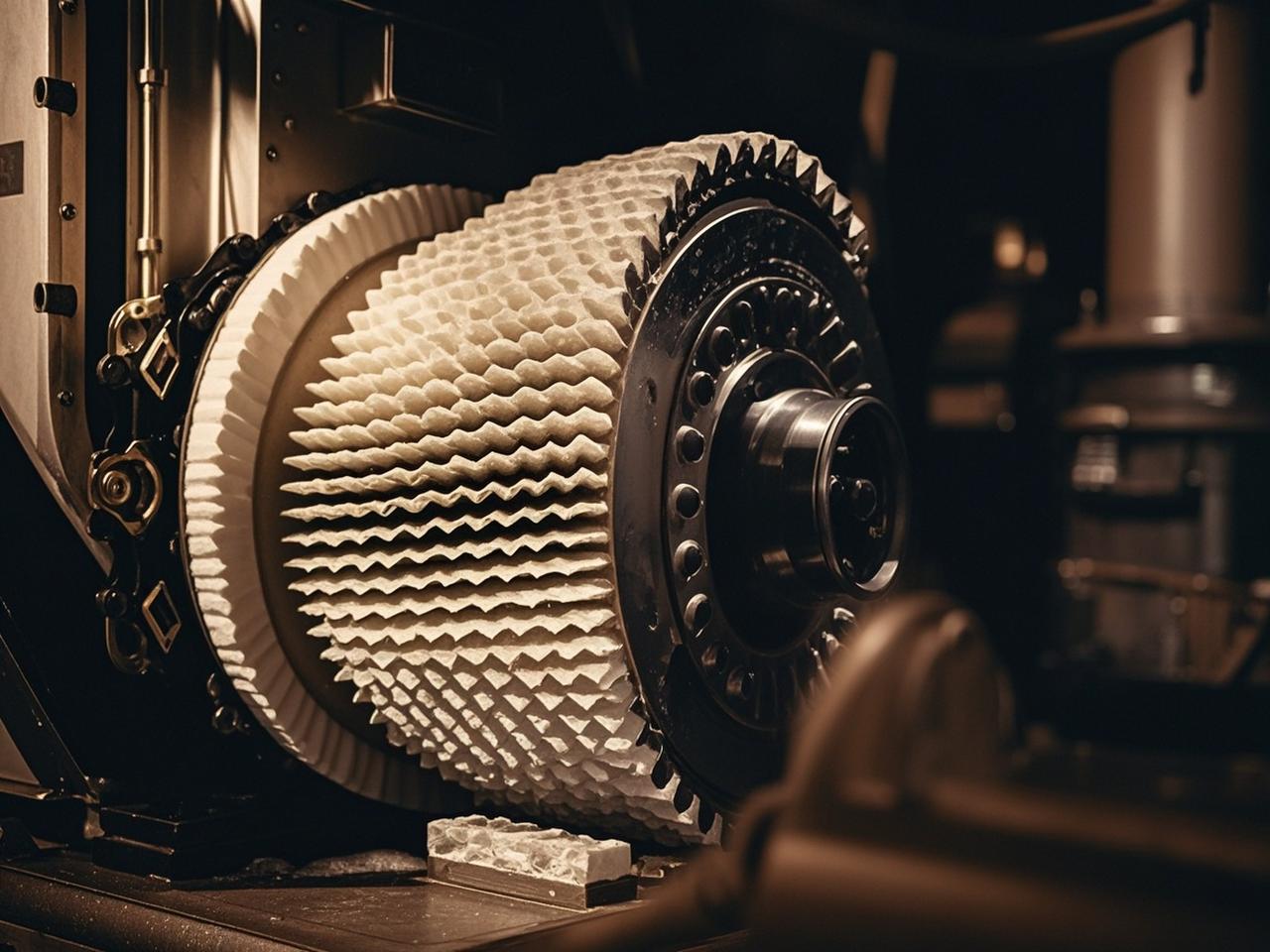

Lubrication of precision moving parts: Robots and automation equipment usually contain many precision moving parts, such as bearings, guides, gears, etc. Ethyl silicone oil lubricants can effectively lubricate these parts, reduce friction and wear, and improve the operation accuracy and stability of the equipment.

Insulation and lubrication of electrical components: In robots and automation equipment, insulation and lubrication of electrical components are equally important. Ethyl silicone oil is widely used in the lubrication and insulation protection of electrical components due to its good dielectric and lubricating properties.

Reduce noise and vibration: Ethyl silicone oil lubricants can effectively reduce the noise and vibration generated by robots and automation equipment during operation, and improve the comfort and stability of the equipment.

3. The impact of ethyl silicone oil lubricants on reliability

Improve equipment life: Ethyl silicone oil lubricants can reduce friction and wear of moving parts of equipment, thereby extending the service life of equipment.

Reduce maintenance costs: Since ethyl silicone oil lubricants have low volatility and good lubrication effects, the frequency of lubricant replenishment and maintenance costs are reduced.

Improve equipment reliability: The application of ethyl silicone oil lubricants can ensure the stable operation of robots and automation equipment under various conditions, thereby improving the reliability of equipment.

In summary, ethyl silicone oil lubricants play an important role in lubrication and reliability in robots and automation equipment. Its excellent properties make it one of the indispensable lubricants in robots and automation equipment.