The structure of the leveling agent for coatings generally consists of two parts that are compatible with the system and those that are incompatible with the system and whose surface tension is lower than that of the system. During the film formation process, due to the separation and migration of the low surface tension incompatible segments, the additives will spontaneously migrate to the surface of the coating system to form a monomolecular film, thereby providing the system with uniform surface tension and eliminating the effect of surface tension gradients. Various surface defects caused by paint film.

Silicone leveling agent is an important category of coating leveling agents. Generally speaking, polydimethylsiloxane with low molecular weight (<5,000) can be used as leveling agent, but due to its phase The capacity is not good, the use is more restricted, and the leveling effect is not good enough, so it cannot be used in high-end systems. At present, the silicone leveling agents widely used in coatings are various modified silicone oils. According to the different types of modification, they mainly include polyether modified silicone oil, polyester modified silicone oil, phenyl modified silicone oil, and alkyl modified silicone oil. Silicone oil, phenyl alkyl co-modified silicone oil and alkyl-polyether co-modified silicone oil, among which polyether modified silicone oil can be adjusted in a wide range due to its structure, and its performance can cover a variety of different requirements, which can be applied to Various systems are currently the main varieties of silicone leveling agents.

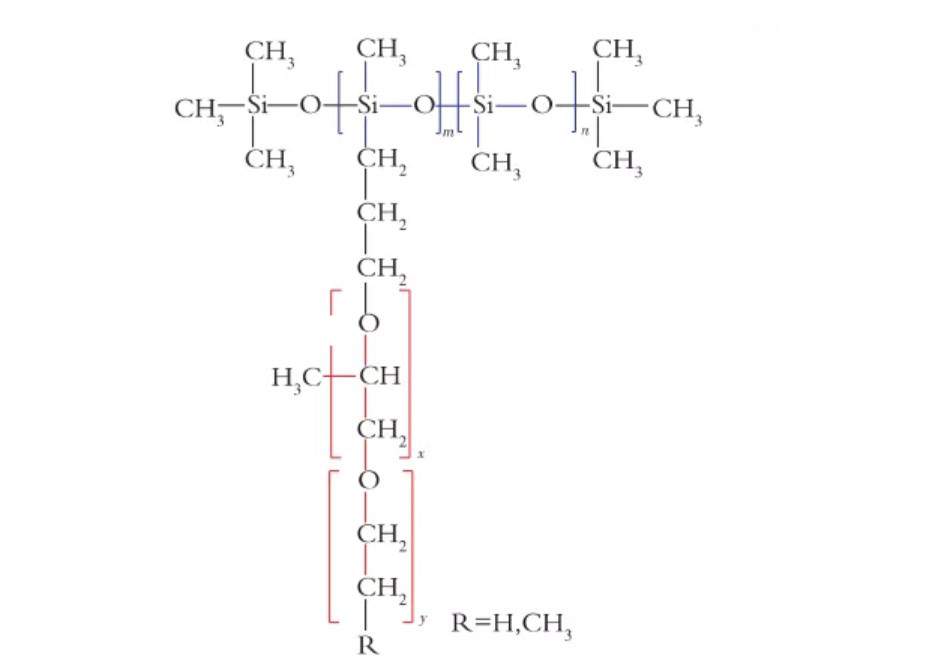

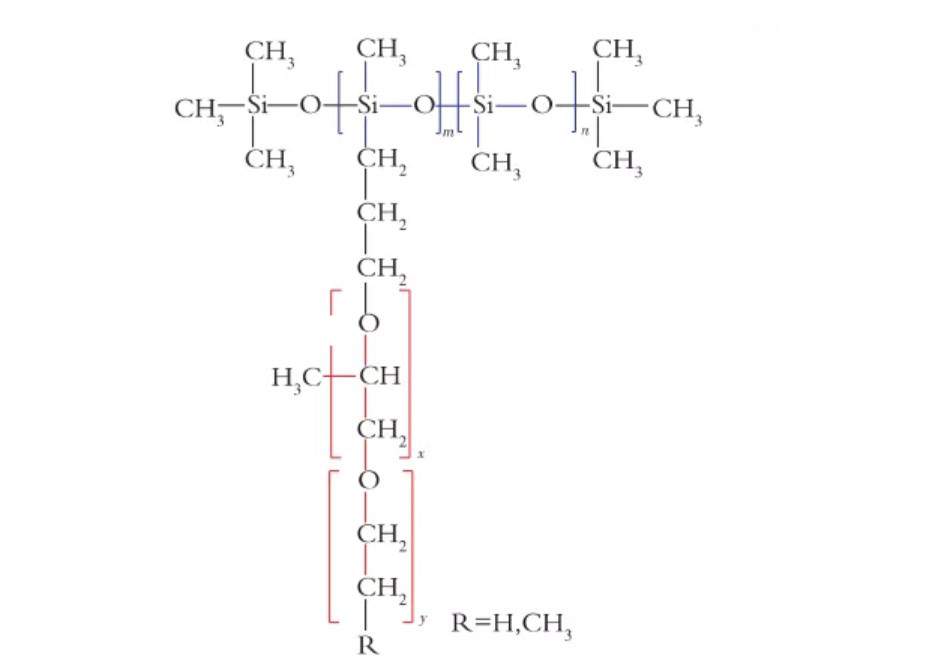

The basic structure of polyether modified silicone is shown in formula (1).

Among them, the values of m and n determine the content of siloxane segments in the structure. The smaller the value of m/n, the higher the corresponding silicon content; and the values of x and y determine the relative molecular mass and hydrophilicity of the polyether segment. (X represents the number of propylene oxide units, which are hydrophobic units, and y represents the number of ethylene oxide units, which are hydrophilic units. When x>y, the polyether segment is mainly hydrophobic, and when x<y, The polyether segment is mainly hydrophilic). The values of m, n, x, and y determine the properties of the corresponding polyether modified silicone oils, and also determine their uses.

If a leveling agent is required to have a better hand feel and anti-crater ability, usually a higher silicon content and a longer siloxane segment length are required, which can be achieved by increasing the m and n values; when leveling is required When the agent has good defoaming ability, it needs higher silicon content and propylene oxide content, which can be achieved by increasing the value of m, n, x and reducing the value of y; When the risk of paint film ills is relatively low, a relatively low silicon content is required, which can be achieved by increasing m and reducing the value of n; when it is used in water-based systems, it needs to have a certain degree of water solubility, so it needs not too high The silicon content and the higher hydrophilic segment ethylene oxide content can meet the requirements by increasing the values of m and y.

When the leveling agent needs to be used in a high-temperature system (such as baking paint), because the decomposition temperature of polyether is low, it is easy to decompose during use, causing some defects on the surface of the paint film, such as poor repainting, shrinkage, etc. It is necessary to choose silicone oil modified with high temperature resistant groups (such as alkyl modified silicone oil, phenyl modified silicone oil, polyester modified silicone oil, etc.). Relatively speaking, alkyl modified silicone oil can provide leveling effects. It also has a good defoaming effect, but its compatibility is not good, and it is usually not suitable for varnishes. The compatibility of phenyl silicone oil and polyester modified silicone oil is relatively good, suitable for use in high temperature varnish systems, while providing excellent compatibility and high temperature resistance.

With the development of technology, some leveling agents combined with silicone and acrylate have recently appeared. This type of leveling agent combines the advantages of the two at the same time, and has excellent early leveling and late leveling effects. According to its chemical structure, it can be divided into two types: acrylate-modified silicone leveling agent (silicone as the main chain and acrylate as the side chain) and silicone-modified acrylate, while silicone-modified acrylate In addition to providing a leveling effect, a leveling agent can also provide an additional anti-fouling effect.