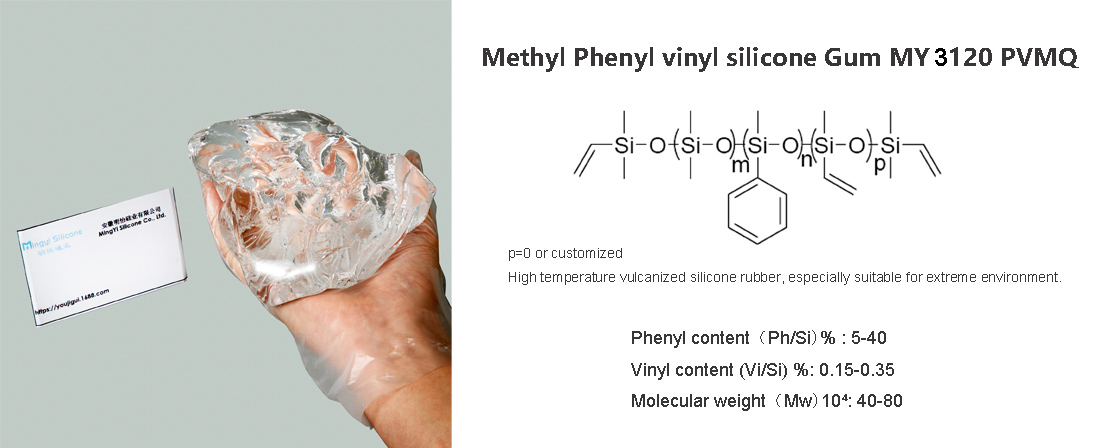

High-performance silicone rubber raw materials MY 3120 Methyl Phenyl vinyl silicone Gum PVMQ

Other Names: Phenyl Vinyl Methyl Silicone, Poly Dimethyl Diphenyl Vinyl Siloxane, PVMQ

Technical index:

This value is a typical data, non product specification value

|

Test |

Unit |

Value |

|

Appearance |

|

colourless |

|

Phenyl content(Ph/Si) |

% |

5-40 |

|

molecular weight(Mw) |

10⁴ |

40-80 |

|

specific gravity(25℃) |

|

0.99-1.05 |

|

volatile(150℃/3h) |

% |

≤2 |

Application:

- In industries such as aviation, electronics, machinery, and chemical, low-temperature resistant sealing materials and waterproof and moisture-proof insulation materials can be manufactured;

- Due to its physiological inertia, it can be used for blood refrigeration sealing and medical tubing in the field of medicine and hygiene;

- It can also be used to manufacture sealing materials, molded products, etc. with special properties such as radiation resistance, high temperature resistance, and erosion resistance.

Store in unopened original packaging at temperatures below 40 ℃ for 24 months from the date of production

Request samples now / Get technical data / Customized delivery quote